Hammer Mill Vibration Problems . If the body or pin hole of the hammer are wearing before the hard facing or if there is. too high of a ratio (>2.5 hp/hammer) may result in poor hammer life. The fan must be sized for the full range of milling system requirements. a hammer mill might operate at a higher vibration level while in use. Proper fan selection, along with proper filter receiver selection, represent the typical problem with many hammermill operations. ensure proper fan selection. Triangular plate or disc cracks; excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges. The fan must be located on the clean side of the filter receiver.

from www.chegg.com

a hammer mill might operate at a higher vibration level while in use. excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges. Proper fan selection, along with proper filter receiver selection, represent the typical problem with many hammermill operations. Triangular plate or disc cracks; The fan must be located on the clean side of the filter receiver. too high of a ratio (>2.5 hp/hammer) may result in poor hammer life. The fan must be sized for the full range of milling system requirements. ensure proper fan selection. If the body or pin hole of the hammer are wearing before the hard facing or if there is.

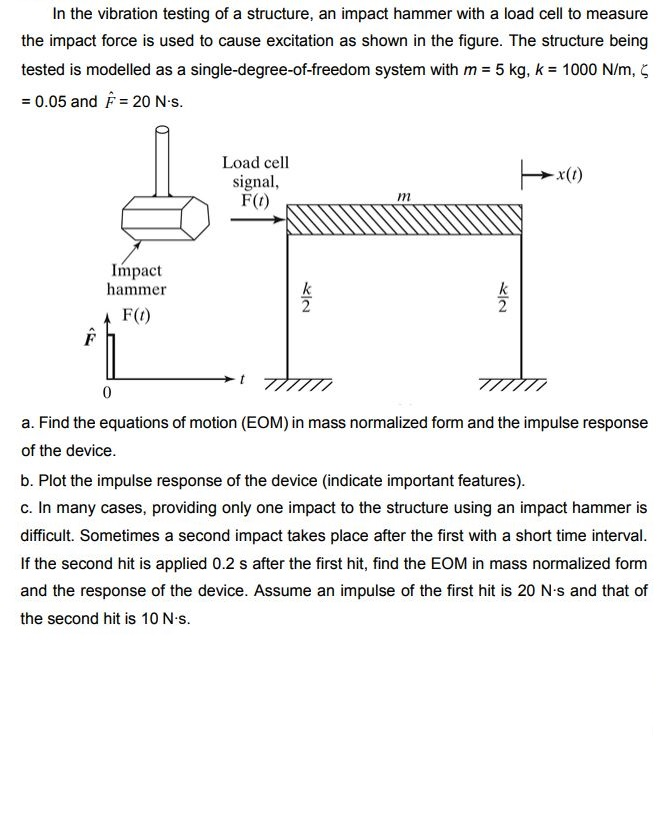

Solved in the vibration testing of a structure, an impact

Hammer Mill Vibration Problems excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges. excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges. Proper fan selection, along with proper filter receiver selection, represent the typical problem with many hammermill operations. too high of a ratio (>2.5 hp/hammer) may result in poor hammer life. If the body or pin hole of the hammer are wearing before the hard facing or if there is. a hammer mill might operate at a higher vibration level while in use. The fan must be located on the clean side of the filter receiver. Triangular plate or disc cracks; The fan must be sized for the full range of milling system requirements. ensure proper fan selection.

From www.researchgate.net

A Conventional Hammer Mill Download Scientific Diagram Hammer Mill Vibration Problems ensure proper fan selection. The fan must be sized for the full range of milling system requirements. Proper fan selection, along with proper filter receiver selection, represent the typical problem with many hammermill operations. Triangular plate or disc cracks; If the body or pin hole of the hammer are wearing before the hard facing or if there is. . Hammer Mill Vibration Problems.

From learnaboutpharma.com

Hammer Mill Principle, Construction, Working, and Advantages Hammer Mill Vibration Problems The fan must be located on the clean side of the filter receiver. The fan must be sized for the full range of milling system requirements. Triangular plate or disc cracks; If the body or pin hole of the hammer are wearing before the hard facing or if there is. Proper fan selection, along with proper filter receiver selection, represent. Hammer Mill Vibration Problems.

From ridzeal.com

Hammer Mill Working Principles, Types, and Applications Hammer Mill Vibration Problems ensure proper fan selection. a hammer mill might operate at a higher vibration level while in use. The fan must be sized for the full range of milling system requirements. If the body or pin hole of the hammer are wearing before the hard facing or if there is. Triangular plate or disc cracks; Proper fan selection, along. Hammer Mill Vibration Problems.

From blog.praterindustries.com

Understanding the Basic Working Principle of Hammer Mills Hammer Mill Vibration Problems The fan must be sized for the full range of milling system requirements. If the body or pin hole of the hammer are wearing before the hard facing or if there is. Proper fan selection, along with proper filter receiver selection, represent the typical problem with many hammermill operations. Triangular plate or disc cracks; ensure proper fan selection. . Hammer Mill Vibration Problems.

From www.millpowder.com

Hammer Milling Crusher Grinder Machine Line Mill Technology Hammer Mill Vibration Problems The fan must be located on the clean side of the filter receiver. too high of a ratio (>2.5 hp/hammer) may result in poor hammer life. Triangular plate or disc cracks; excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges. If the body or pin hole of the hammer are. Hammer Mill Vibration Problems.

From www.semanticscholar.org

Figure 3 from Development on a Hammer Mill with Separate Sieving Device Hammer Mill Vibration Problems The fan must be located on the clean side of the filter receiver. ensure proper fan selection. a hammer mill might operate at a higher vibration level while in use. Proper fan selection, along with proper filter receiver selection, represent the typical problem with many hammermill operations. Triangular plate or disc cracks; If the body or pin hole. Hammer Mill Vibration Problems.

From www.researchgate.net

Schematics of a rotating (a) hammer mill and (b) cutting mill, with Hammer Mill Vibration Problems If the body or pin hole of the hammer are wearing before the hard facing or if there is. Triangular plate or disc cracks; The fan must be located on the clean side of the filter receiver. too high of a ratio (>2.5 hp/hammer) may result in poor hammer life. a hammer mill might operate at a higher. Hammer Mill Vibration Problems.

From www.indiamart.com

Internal Hammer Mill Dynamic Balancing Service, For Industrial Hammer Mill Vibration Problems ensure proper fan selection. Triangular plate or disc cracks; If the body or pin hole of the hammer are wearing before the hard facing or if there is. excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges. Proper fan selection, along with proper filter receiver selection, represent the typical problem. Hammer Mill Vibration Problems.

From www.chemicalslearning.com

Hammer Mill Principle Construction, Working and Advantages Hammer Mill Vibration Problems ensure proper fan selection. too high of a ratio (>2.5 hp/hammer) may result in poor hammer life. The fan must be sized for the full range of milling system requirements. excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges. The fan must be located on the clean side of. Hammer Mill Vibration Problems.

From learnaboutpharma.com

Hammer Mill Principle, Construction, Working, and Advantages Hammer Mill Vibration Problems a hammer mill might operate at a higher vibration level while in use. The fan must be sized for the full range of milling system requirements. excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges. too high of a ratio (>2.5 hp/hammer) may result in poor hammer life. Triangular. Hammer Mill Vibration Problems.

From pharmaguddu.com

Hammer Mill; Usage, Construction, Working Principles, and Types Hammer Mill Vibration Problems Triangular plate or disc cracks; a hammer mill might operate at a higher vibration level while in use. The fan must be sized for the full range of milling system requirements. ensure proper fan selection. Proper fan selection, along with proper filter receiver selection, represent the typical problem with many hammermill operations. If the body or pin hole. Hammer Mill Vibration Problems.

From www.911metallurgist.com

Hammer Mill Operating Principle Hammer Mill Vibration Problems a hammer mill might operate at a higher vibration level while in use. The fan must be located on the clean side of the filter receiver. If the body or pin hole of the hammer are wearing before the hard facing or if there is. Proper fan selection, along with proper filter receiver selection, represent the typical problem with. Hammer Mill Vibration Problems.

From www.chemicalslearning.com

Hammer Mill Principle Construction, Working and Advantages Hammer Mill Vibration Problems Triangular plate or disc cracks; a hammer mill might operate at a higher vibration level while in use. The fan must be sized for the full range of milling system requirements. too high of a ratio (>2.5 hp/hammer) may result in poor hammer life. excessive wear of the hammer holes or grooving of the pins generally indicated. Hammer Mill Vibration Problems.

From www.researchgate.net

Schematic of design hammer mill 1Main frame ,2Single phase Electrical Hammer Mill Vibration Problems Proper fan selection, along with proper filter receiver selection, represent the typical problem with many hammermill operations. too high of a ratio (>2.5 hp/hammer) may result in poor hammer life. The fan must be sized for the full range of milling system requirements. a hammer mill might operate at a higher vibration level while in use. The fan. Hammer Mill Vibration Problems.

From www.youtube.com

Hammer Mill Principle Construction and Working,Hammer Mill Advantages Hammer Mill Vibration Problems Triangular plate or disc cracks; The fan must be located on the clean side of the filter receiver. ensure proper fan selection. The fan must be sized for the full range of milling system requirements. Proper fan selection, along with proper filter receiver selection, represent the typical problem with many hammermill operations. too high of a ratio (>2.5. Hammer Mill Vibration Problems.

From www.youtube.com

Classification of Size Reduction Equipment and Hammer Mill,B.pharma 3rd Hammer Mill Vibration Problems Triangular plate or disc cracks; The fan must be located on the clean side of the filter receiver. Proper fan selection, along with proper filter receiver selection, represent the typical problem with many hammermill operations. The fan must be sized for the full range of milling system requirements. If the body or pin hole of the hammer are wearing before. Hammer Mill Vibration Problems.

From www.iqsdirectory.com

Mills What are they? How are Mills used? Advantages Hammer Mill Vibration Problems excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges. The fan must be sized for the full range of milling system requirements. a hammer mill might operate at a higher vibration level while in use. ensure proper fan selection. Proper fan selection, along with proper filter receiver selection, represent. Hammer Mill Vibration Problems.

From www.chegg.com

Solved in the vibration testing of a structure, an impact Hammer Mill Vibration Problems excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges. The fan must be located on the clean side of the filter receiver. The fan must be sized for the full range of milling system requirements. ensure proper fan selection. Triangular plate or disc cracks; a hammer mill might operate. Hammer Mill Vibration Problems.